Glass Surface Solutions

The Vetrox Glass Polishing System

Precision mechanical glass polishing

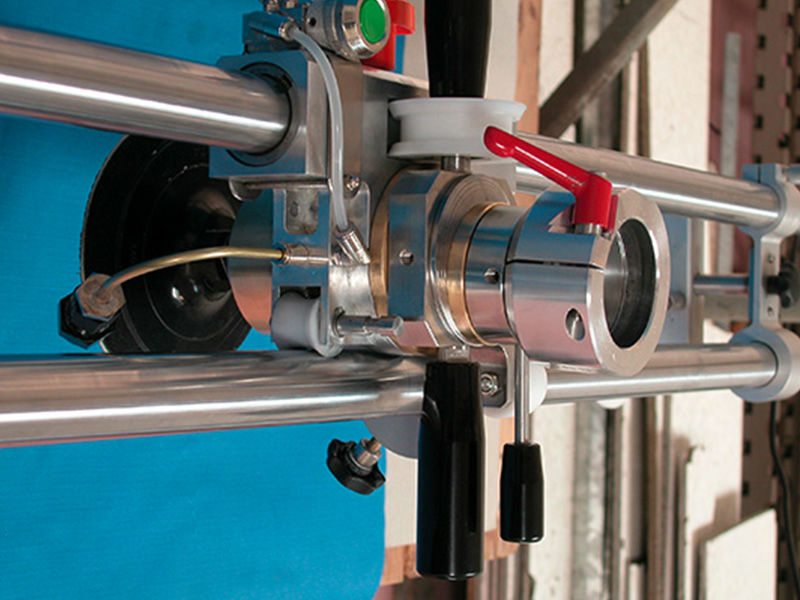

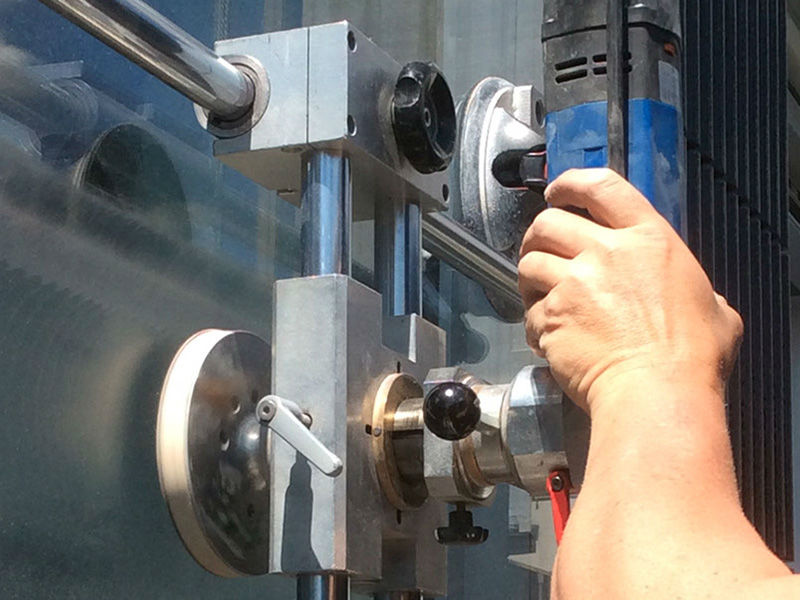

Vetrox and its key component; the Vetromat were designed by mechanical engineer Bernhard Dur in his workshop situated near the shore of Lake Zurich. The Vetromat has an alloy cast frame comprising of 50 parts enabling total control throughout the polishing process.

The Vetromat

The fixed system clamps the electric motor allowing smooth delivery of the mechanical torque, this enables large areas to be polished at one time with minimal physical exertion. We can use 3000-watt motors, more than twice as powerful as any hand held polisher.

The cutting angle can be adjusted from 0 to 5 degrees allowing for precise feathering.

The weight on the polishing surface can be closely monitored and applied evenly over large areas.

The Disks

Our disks are also unique, they comprise of a pyramid matrix that ensure a uniform grit rating as they wear.

Once completed our finish is P5000 or 3 microns, at least as fine as the smooth air side surface of the glass when it was first molten from silica sand.

The Know How

Testing and design: The key to our service is the continuous in-house testing of new products and the designing of improved systems that takes place in our head office laboratories.

Training: Training starts at our head office in Switzerland and an open environment with regular briefings ensures knowledge is quickly shared.

Experience: Glass polishing is an artisan skill and we have completed over 3000 projects across Europe and several in the USA for distinguished clients.